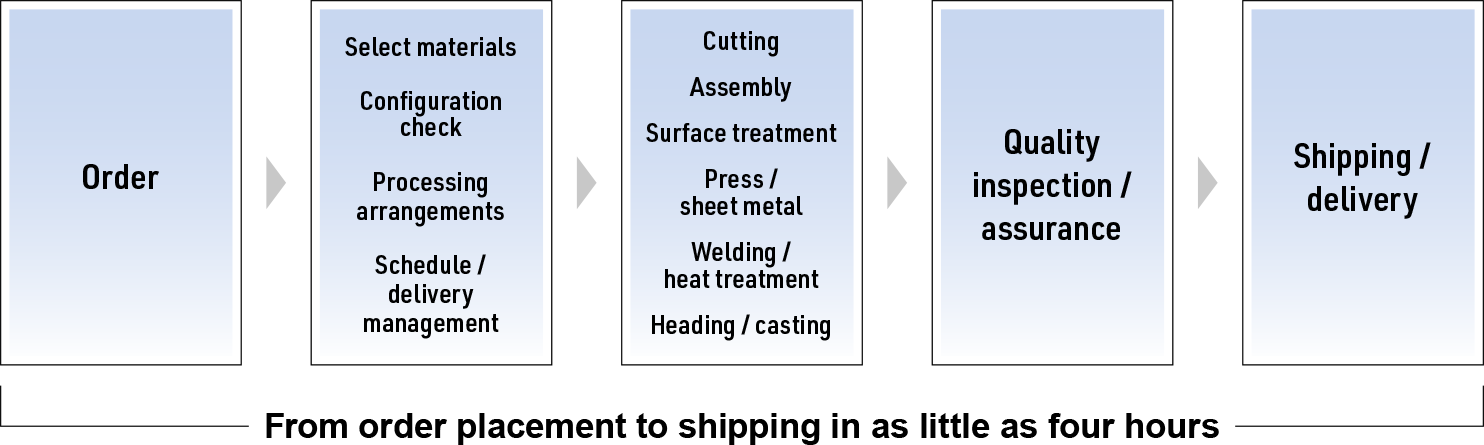

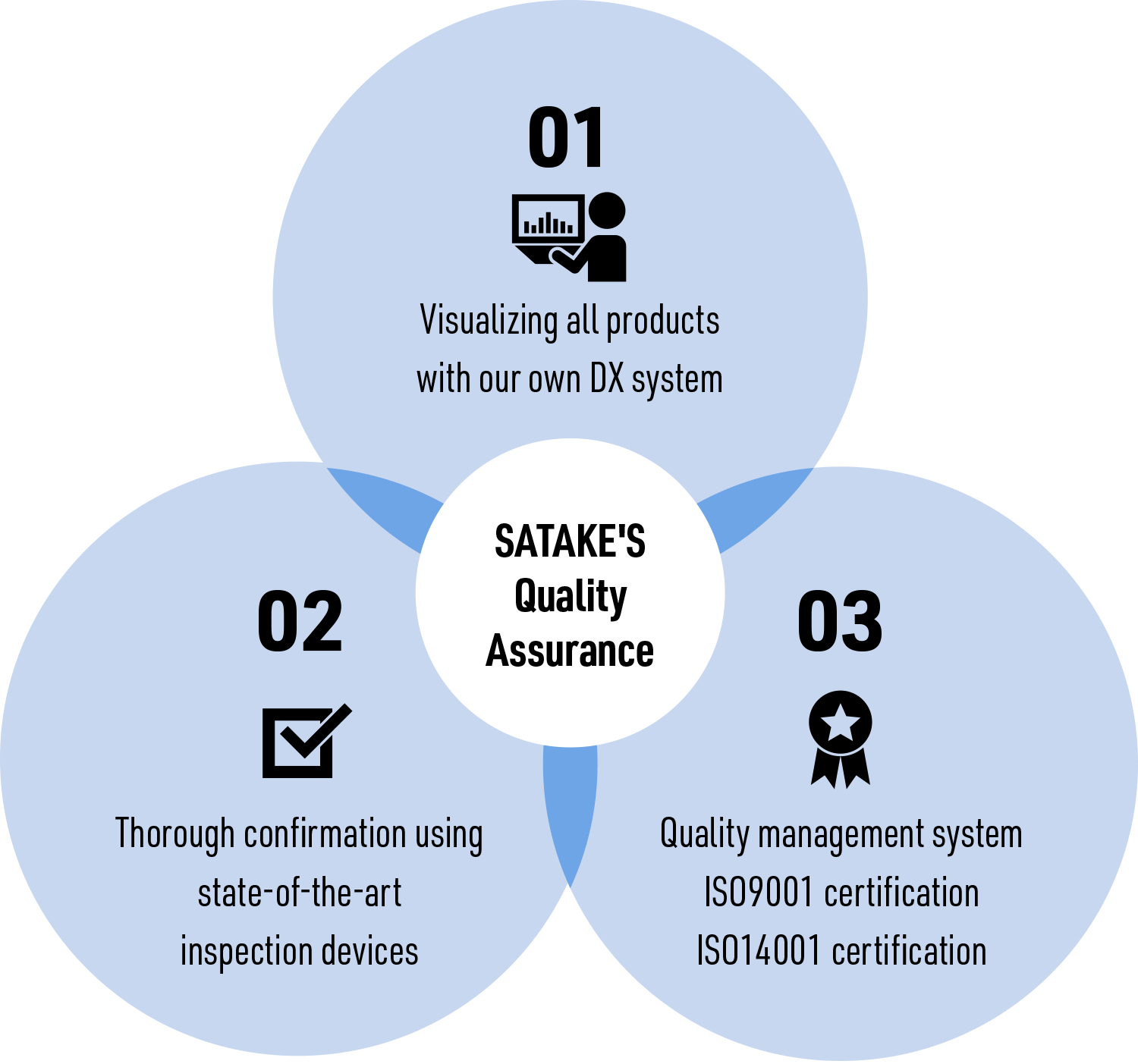

01. Visualizing all products with our own DX system

We have our own SEs, developed our own system, and operate it on an on-premise server.

We have 300,000 types of metal parts in our product lineup, and we are able to process and ship 2,000 different orders every day on the same day, realizing ultra-high-mix, small-lot production because our DX technology, which visualizes the movement of all orders from the moment they are received to the moment they are shipped, is the foundation of our system.

02. Thorough confirmation using state-of-the-art inspection devices

SATAKE Precision Technology’s Quality Assurance Division leads inspections during each step of the manufacturing process, from material receiving to packaging and shipping. These inspections are performed using general measuring devices and state-of-the-art inspection devices. We inspect our products closely, managing their quality systematically, with the aim of producing zero defects. This guarantees the high quality of our products.

03. Quality management system

SATAKE Precision Technology has defined a quality policy aimed at improving customer satisfaction, and all business sites have received ISO9001 certification (ISO9001 is an international quality management standard). We will continue to make ongoing improvements and strive to provide a steady and rich selection of superior products and services. We have also obtained quality and environmental ISO certification. Our goal is not merely to obtain certification, but to fully integrate our management systems to provide greater value.